Modular Conveyor

MODU has made significant progress in the conveyor business, surging ahead of its competitors to provide a one-stop modular conveyor system. A proven track record further accentuates this in the international business arena, widespread acceptance and recognition of its superior product, innovative design and professional service.

PLASTIC CHAIN

PLASTIC BELT

SPIRAL CONVEYOR

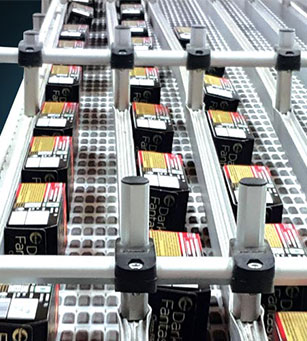

We provide diverse plastic chain conveyor systems. All conveyor systems can be effortlessly assembled with standard tools.

The components are prepared with anodized aluminium and moulded plastic, giving a spotless and aesthetic outlook. A ready stock availability Of conveyor components are ensured at all times. The bends, straights and supports are made up of pre-assembled pieces in which conveyors can be assembled in a lesser time using simple hand tools.

The new modular plastic belt conveyor system is a simplified solution for conveying large products. All components of the plastic belt conveyor are standardized for easy engineering, maintenance and operation. Simplicity in its design makes new plastic belt conveyor reliable, flexible, safe and adaptive to any requirements. The white POM belt surface is nat and smooth which minimizes the risÄ Of scratches on products, allowing safe handling Of sensitive products. Plastic belt conveyor systems are designed to integrate with new and existing production equipment. Machinery that has been laid out to fulfill factory and operator requirement can easily be linÄed using suitable components and conveyors from our modular range.

The new modular plastic belt conveyor system is a simplified solution for conveying large products. All components of the plastic belt conveyor are standardized for easy engineering, maintenance and operation. Simplicity in its design makes new plastic belt conveyor reliable, flexible, safe and adaptive to any requirements. The white POM belt surface is nat and smooth which minimizes the risÄ Of scratches on products, allowing safe handling Of sensitive products. Plastic belt conveyor systems are designed to integrate with new and existing production equipment. Machinery that has been laid out to fulfill factory and operator requirement can easily be linÄed using suitable components and conveyors from our modular range.

ACCUMULATION CONVEYOR

Table - Accumulation

Alphine - Accumulation

S – Accumulation

The accumulation table stores products to generate mass buffering to accommodate other processes with a large storage capacity. This equipment is driven by two gear motors which drive alternating conveyor with opposite direction.

Alpine-Accumulation conveyor acts as a buffer between machines. It consists of many conveyor layers which are stacked above each other. Alpine accumulation conveyor system can be used for cooling, drying and buffering.

Accumulation conveyor provides in-line “first-in-first-out” accumulation of products. It maintains product orientation while providing accumulation between line operations. Sanitary clean design suited for pharmaceutical operation.

ELEVATING & LOWERATING CONVEYOR

Gripper Conveyor

Elevator/Lowerator

Friction and Cleated Conveyor

A gripper conveyor is a system that utilizes two sets of conveyors set up in a gripping format to move a product from a lower elevation to an upper elevation or vice versa, with the benefit of taking up less floor space. It grips the product in a firm but gentle manner before releasing it onto another conveyor. It is an ideal assembly for high-speed production or packaging line.

Elevator/Lowerator is designed with high speed, payload and capacity, mainly to convey cases, bags and trays. It takes up less floor space in case/carton palletizing lines, warehousing, or work-in-progress storage applications by transferring products to an overhead conveyor section. Thus, creating aisleways, clearance for forklifts and transfer products between floors.

Friction and cleated conveyor are a cost-effective and straightforward way to bring a product from one level to another. When elevating the production flow, you reclaim valuable floor space, enabling you to add more production capacity and increase accessibility. Refined design and standardized interfaces to the upstream and downstream equipment make the solution efficient and accommodating various products.