INDUSTRIAL ROBOT & COBOT

Robotic solutions from MODU System are designed to reduce labor-intensive production processes.

MATERIAL FEEDING

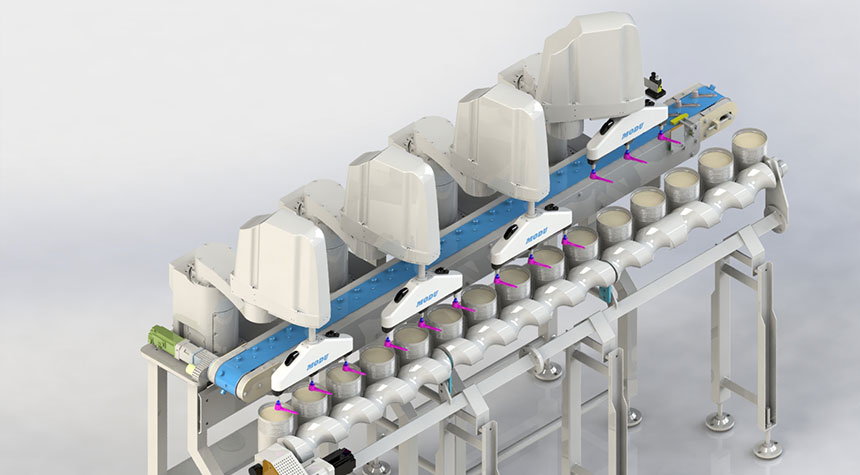

The requirement to use a collaborative robot or SCARA robot for material feeding at any phase of the production process increases rapidly.

Modern production facilities such as food and dairy, personal healthcare, EV battery lines and machined parts assembly lines and are beginning to see the value of introducing collaborative material feeding robots

This robotic solution can be applied in many sections of your production facilities as below :

• Pick and place of material into products. (eg. Pick and place of scoops into tin cans)

• Pick and place for industrial machines (CNC)

• Components assembly

These solutions are customized to meet individual production requirements.Contact us to discuss further your material feeding application.

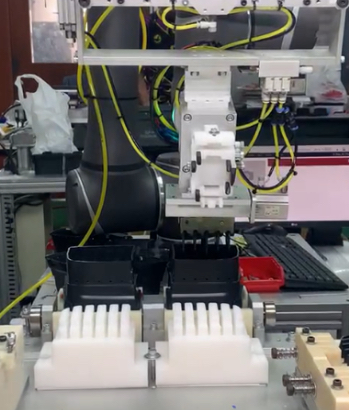

Scoop pick and place in to tin cans

Components assembly using collaborative robot

CASE PACKING

MODU's case packer solution takes finished products from the middle of the production line and places them into a box. Keeping in mind the production space availability, MODU has design compact and efficient.

These solutions are customized to meet individual production requirements.

Contact us to discuss further on your material feeding application.

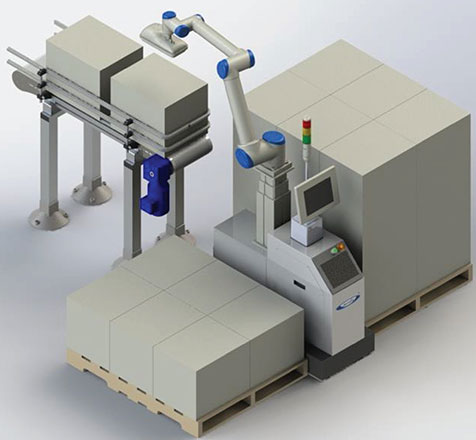

COBOT PALLETIZING

MODU’s cobot palletizers are modular and cost-effective solutions to palletize a wide variety of products. Equipped with an intuitive operator interface, cobot palletizers are available in one- or two-pallet configurations, with various options for infeed conveyor, end of arm tooling and safety.

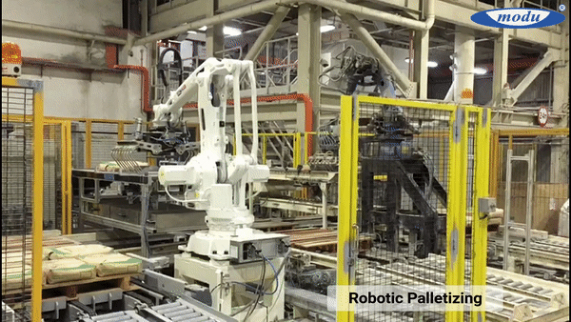

PALLETIZING

Palletization may be one of the last steps in the packaging sequence before your product gets loaded onto the truck and distributed to retailers or warehouses; however, it is also one of the most injury-prone tasks especially when done manually. As such, palletizing often ends up being the first part of a line that gets automated.

MODU System has an excellent experience of integrating robotic case palletizers throughout the world. With the ability to provide highly customized solutions, implement cutting-edge technologies, and take a consultative approach to working with you, MODU System is your partner for palletizing solutions.